4-way Diverting Valve - FRANKLIN

The Franklin DuraSeal™ 4-Way Diverter Valve is a resilient seated, non-lubricated plug type valve which utilizes a mechanical action to perform diverting functions.

Operation

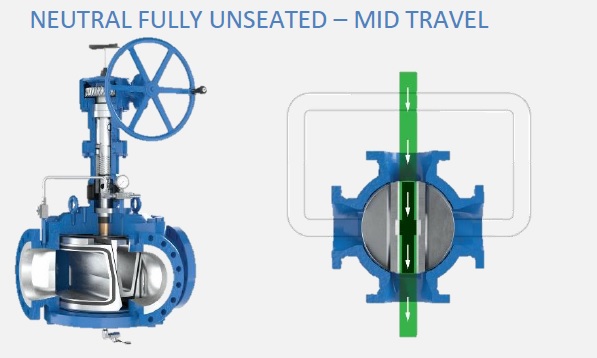

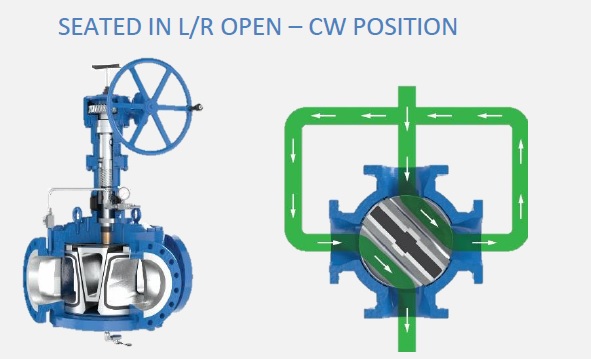

When diverting the flow, turn or actuate the operator clockwise or counterclockwise dependent on desired flow path, the plug will raise, retracting the seating slips through their tapered dovetail connections.

Once the seals are fully retracted, the plug and slips perform a 90° rotation, free of any seal surface abrasion.

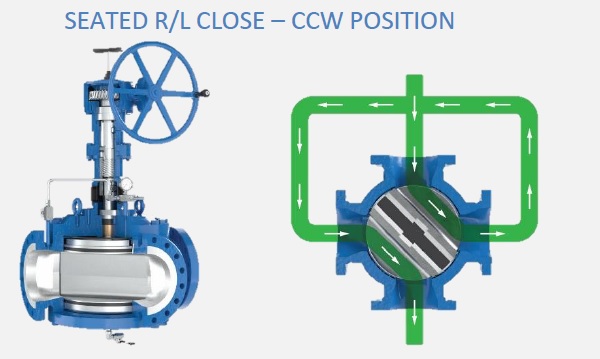

Upon completing the 90°rotation, the plug is driven down between the tapered surfaces of the slips, causing expansion of the seals into the sealing surface for a positive seal.

Once seated the pressure gauge will indicate reduced pressure, proving the seal.

FRANKLIN Duraseal 4-way valve meets standards required by Oil&Gas industry, such as:

- API6D

- ASME B16.34

- ASME B16.5

Duraseal valve offers tight sealing, providing reliable operation and long lifetime,

Its Differential Thermal Relief system (DTR) provides the cavity relief functions of API 6D and its pressure gauge allows to check integrity of seals

Characteristics and Advantages

- In-line Maintenance: Duraseal valve allows doing maintenance without taking valve out of the line, reducing operating costs and downtime. Slips are designed to be mounted to dovetail connections on the Plug allowing for removal from either the top or bottom of the valve without removing the valve from the line and without influencing the Actuator.

- Double Protection Mechanical Seal: during rotation of the plug there is no abrasion or wear between the sealing surfaces. The mechanical retraction and compression ensure a no leak stream separation and a longer seal life. Seals are made of highly resilient elastomers and valve does not require sealant under any circumstances to seal.

- Low torque operation: manual and motorized operation can be possible with the use of an electric actuator. With lower cycling torques, smaller and less expensive actuators can be used.

Specifications

- Diameters/Class: 4” #150 – 2”, 3”, 4” #300 - 2”, 3” #600.

- Body in A216 WCB, WCC, A3512 LCC, A351 CF8M.

- Nickel Plated Plug - ASTM A216 Gr. WCB, WCC, A352 LCC or 17-4PH.

- Ductile Iron or 17-4PH cast slips with vulcanized seal.

- Manual operated or electric actuator automatized.

APPLICATIONS

- Bi-Directional Meter Prover.

- Multi-Product Manifolds

- Metering Systems

- Custody Transfer Units

- Terminals

- Tank Farms (Oil Depots)

- Fuel Loading Systems